Empower your warehouse to perform smarter, streamline business processes and maximize space utilization

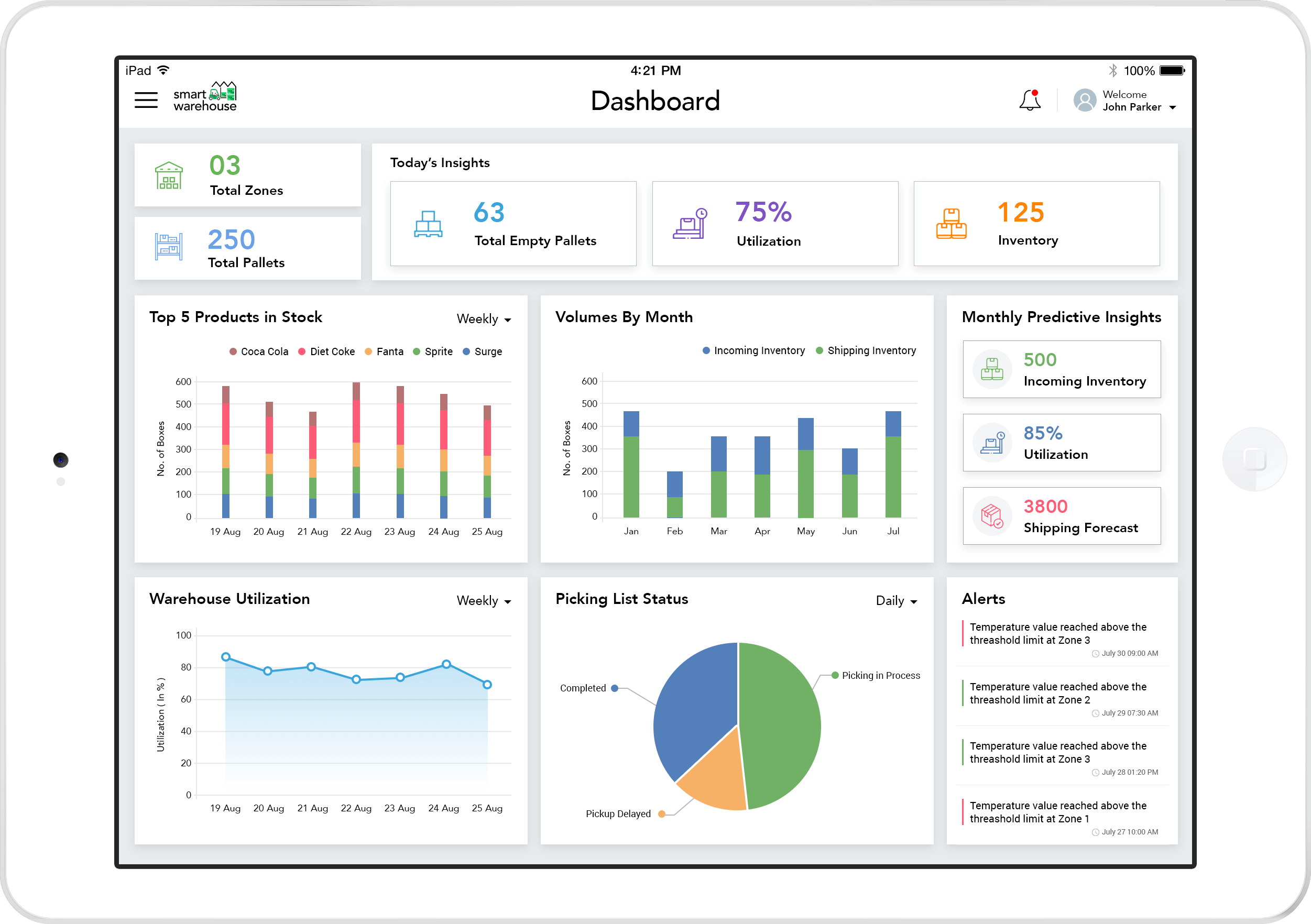

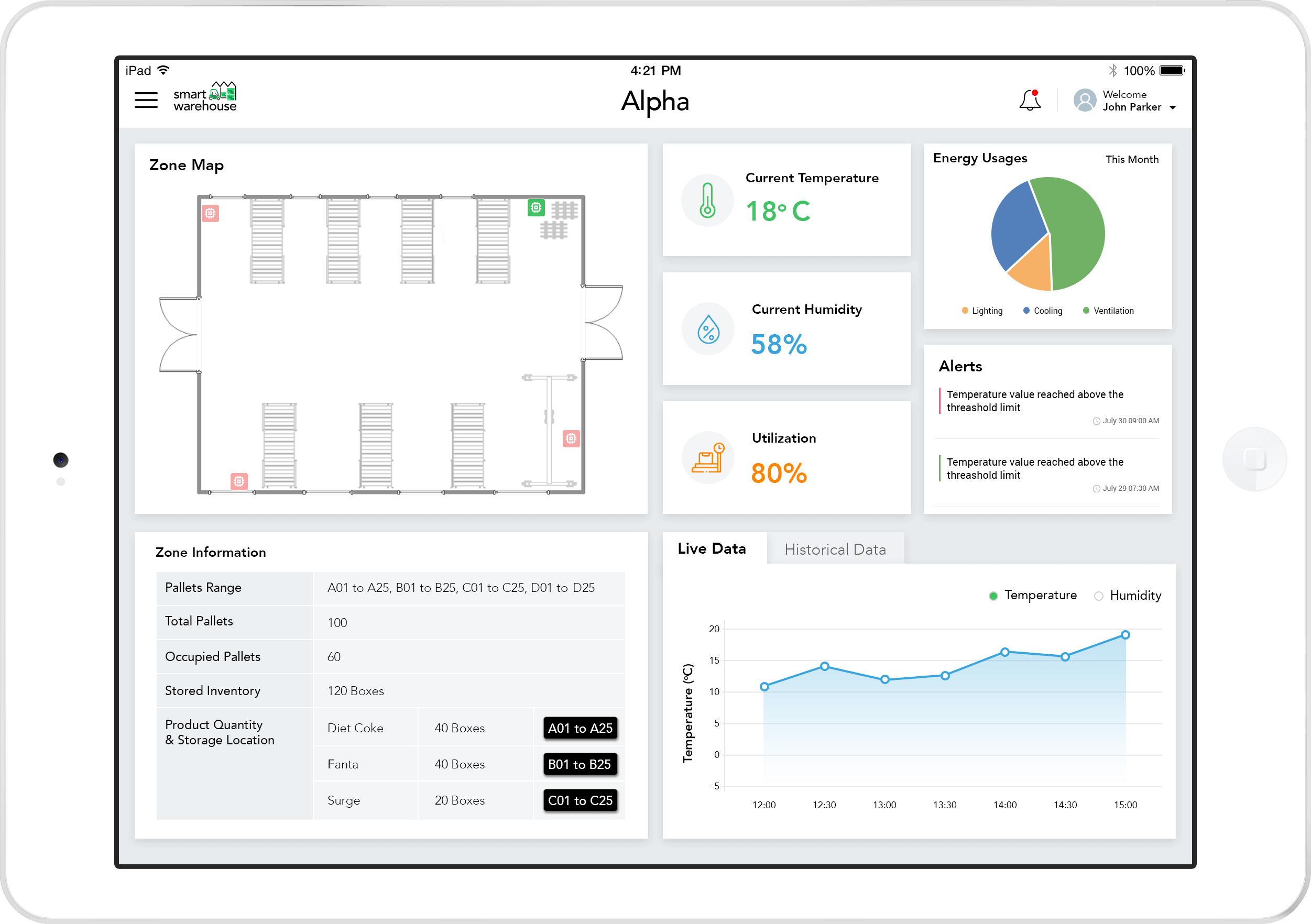

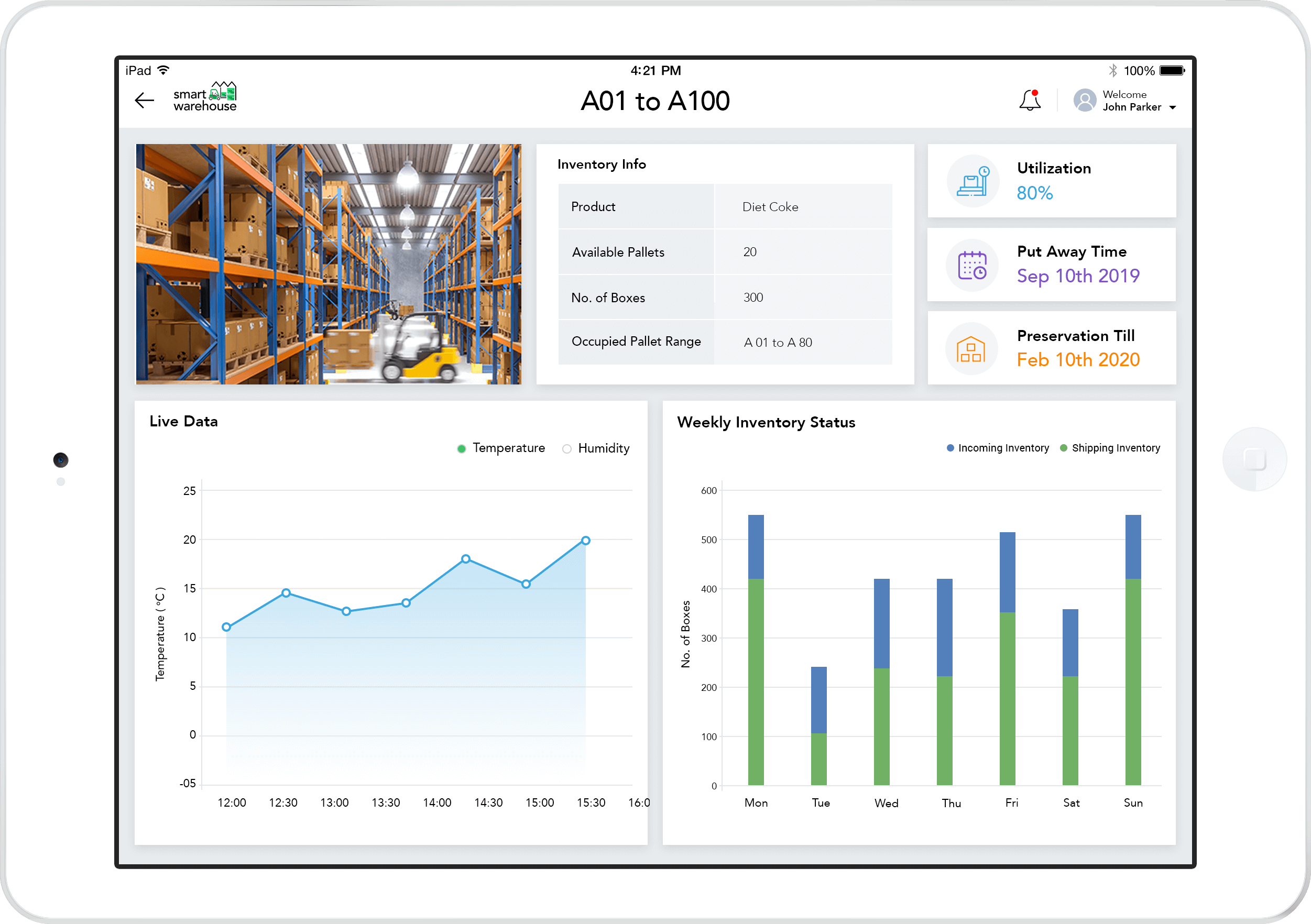

Today, warehouses are more than storage and inventory facilities. Many organizations are therefore investing in IoT-enabled warehouses for better automated control systems (ACS) and warehouse management systems (WMS) to improve their operational efficiency by reducing costs. Our Smart Warehouse Monitoring solution enables real-time monitoring of warehouse assets/equipment by providing transparency and traceability of all goods across different locations. The collected data generates meaningful insights on the status of inventory and storage and gives visibility of the stock. It helps the warehouse operator to prevent inventory shrinkage and improves the safety of workers. Such valuable insights also help to optimize storage locations, pallet journeys, warehouse throughput and workforce.

Key Challenges

-

Lack of end-to-end inventory visibility

-

Consignment damages

-

Poor storage utilization

-

Redundant processes

-

Longer TAT for picking and packing process

-

Errors in order processing

Features

Our Smart Warehouse Monitoring Solution is designed to help organizations keep an automated track of all inventory-related activities. Our solution facilitates business managers to achieve increased profitability, performance and accuracy as well as provide widespread support for fleet management to enhance logistics.

KPIs for warehouse management

-

Productivity and turnover rate

-

Inventory on-hand and inventory flow

-

Order fill rate

-

Pick & pack efficiency

-

Occupancy management

-

Inventory health monitoring